[ad_1]

Thirty decades back, a botanist in Germany experienced a basic want: to see the inner workings of woody vegetation with out dissecting them. By bleaching absent the pigments in plant cells, Siegfried Fink managed to produce transparent wood, and he posted his approach in a specialized niche wooden know-how journal. The 1992 paper remained the final word on see-through wood for a lot more than a ten years, right until a researcher named Lars Berglund stumbled across it.

Berglund was encouraged by Fink’s discovery, but not for botanical causes. The components scientist, who performs at KTH Royal Institute of Know-how in Sweden, specializes in polymer composites and was fascinated in producing a a lot more sturdy substitute to clear plastic. And he was not the only one particular interested in wood’s virtues. Throughout the ocean, researchers at the University of Maryland were being fast paced on a relevant purpose: harnessing the power of wooden for nontraditional functions.

Now, right after decades of experiments, the investigation of these groups is beginning to bear fruit. Clear wooden could quickly obtain works by using in tremendous-powerful screens for smartphones in delicate, glowing light fixtures and even as structural functions, these types of as coloration-changing windows.

“I genuinely consider this content has a promising upcoming,” states Qiliang Fu, a wood nanotechnologist at Nanjing Forestry University in China who worked in Berglund’s lab as a graduate scholar.

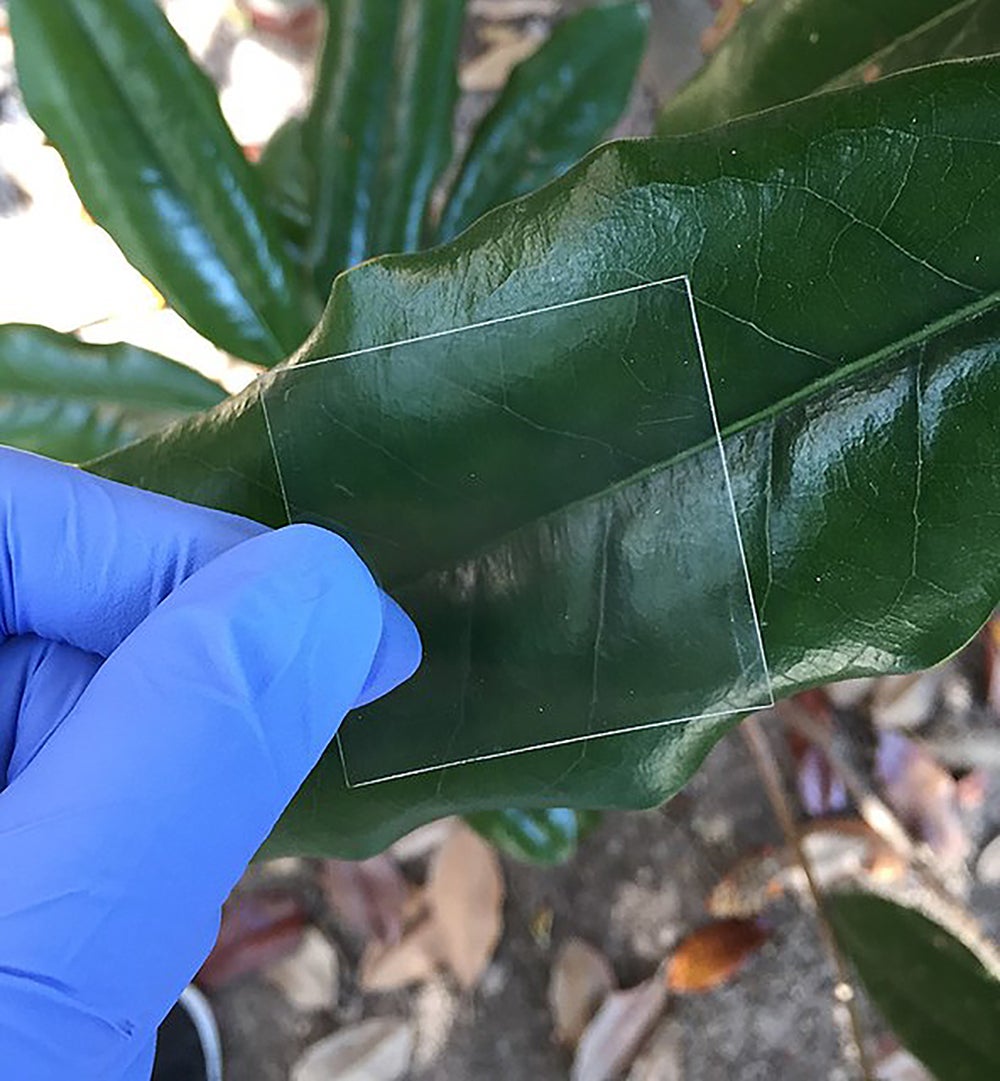

Wood is built up of many tiny vertical channels, like a limited bundle of straws certain jointly with glue. These tube-shaped cells transportation drinking water and vitamins throughout a tree, and when the tree is harvested and the moisture evaporates, pockets of air are remaining behind. To make see-through wood, scientists initial will need to modify or get rid of the glue, called lignin, that holds the cell bundles with each other and supplies trunks and branches with most of their earthy brown hues. Soon after bleaching lignin’s color away or otherwise eradicating it, a milky-white skeleton of hollow cells remains.

This skeleton is however opaque, because the cell partitions bend gentle to a distinct degree than the air in the cell pockets does — a price identified as a refractive index. Filling the air pockets with a substance like epoxy resin that bends light to a similar diploma to the cell partitions renders the wooden clear.

The content the researchers labored with is thin — usually a lot less than a millimeter to about a centimeter thick. But the cells generate a sturdy honeycomb structure, and the little wood fibers are much better than the very best carbon fibers, suggests resources scientist Liangbing Hu, who prospects the research group functioning on transparent wood at the University of Maryland in University Park. And with the resin added, transparent wooden outperforms plastic and glass: In exams measuring how simply resources fracture or crack less than tension, transparent wooden arrived out all-around 3 instances much better than clear plastics like Plexiglass and about 10 occasions harder than glass.

“The success are wonderful, that a piece of wooden can be as robust as glass,” says Hu, who highlighted the functions of transparent wooden in the 2023 Once-a-year Review of Materials Study.

The approach also works with thicker wood but the watch by means of that material is hazier simply because it scatters far more mild. In their initial research from 2016, Hu and Berglund equally uncovered that millimeter-thin sheets of the resin-loaded wood skeletons enable as a result of 80 to 90 % of mild. As the thickness gets closer to a centimeter, gentle transmittance drops: Berglund’s team noted that 3.7-millimeter-thick wood — about two pennies thick — transmitted only 40 % of light.

The trim profile and power of the substance usually means it could be a good choice to merchandise created from skinny, easily shattered cuts of plastic or glass, such as screen screens. The French business Woodoo, for instance, utilizes a identical lignin-eliminating process in its wooden screens, but leaves a little bit of lignin to produce a diverse coloration aesthetic. The corporation is tailoring its recyclable, touch-sensitive digital shows for items which include car or truck dashboards and advertising and marketing billboards.

But most exploration has centered on transparent wooden as an architectural element, with windows a specially promising use, claims Prodyut Dhar, a biochemical engineer at the Indian Institute of Technologies Varanasi. Clear wooden is a significantly far better insulator than glass, so it could aid properties keep warmth or preserve it out. Hu and colleagues have also utilised polyvinyl alcoholic beverages, or PVA — a polymer employed in glue and foods packaging — to infiltrate the wooden skeletons, making transparent wood that conducts heat at a rate 5 moments decrease than that of glass, the crew documented in 2019 in Highly developed Useful Materials.

And researchers are coming up with other tweaks to raise wood’s skill to hold or launch warmth, which would be helpful for strength-productive buildings. Céline Montanari, a products scientist at Increase Investigate Institutes of Sweden, and colleagues experimented with stage-transform products, which flip from storing to releasing warmth when they transform from sound to liquid, or vice-versa. By incorporating polyethylene glycol, for instance, the researchers located that their wooden could shop heat when it was warm and launch heat as it cooled, get the job done they posted in ACS Applied Resources and Interfaces In 2019.

Transparent wooden home windows would consequently be stronger and support in temperature manage improved than common glass, but the view by means of them would be hazy, additional very similar to frosted glass than a typical window. Having said that, the haziness could be an benefit if buyers want diffuse gentle: Because thicker wooden is robust, it could be a partly load-bearing gentle resource, Berglund states, perhaps acting as a ceiling that presents gentle, ambient gentle to a home.

Hu and Berglund have ongoing to toy with ways to bestow new qualities on transparent wooden. All over 5 years ago, Berglund and colleagues at KTH and Georgia Institute of Technological know-how uncovered they could mimic smart home windows, which can switch from clear to tinted to block visibility or the Sun’s rays. The scientists sandwiched an electrochromic polymer — a material that can transform shade with electrical energy — involving layers of clear wooden coated with an electrode polymer to perform electrical power. This created a pane of wooden that modifications from clear to magenta when buyers operate a little electrical current as a result of it.

Much more a short while ago, the two groups have shifted their attention to bettering the sustainability of clear wooden manufacturing. For illustration, the resin utilised to fill the wood scaffolding is ordinarily a petroleum-derived plastic solution, so it is improved to steer clear of utilizing it, Montanari says. As a substitute, she and colleagues invented a absolutely bio-dependent polymer, derived from citrus peels. The group initial blended acrylic acid and limonene, a chemical extracted from lemon and orange rinds which is discovered in vital oils. Then they impregnated delignified wooden with it. Even with a fruity filling, the bio-dependent transparent wood maintained its mechanical and optical properties, withstanding around 30 megapascals of force much more than typical wood and transmitting about 90 per cent of light, the researchers documented in 2021 in State-of-the-art Science.

Hu’s lab, in the meantime, recently described in Science Improvements a greener lignin-bleaching technique that leans on hydrogen peroxide and UV radiation, further more minimizing the vitality calls for of manufacturing. The group brushed wooden slices ranging from about .5 to 3.5 millimeters in thickness with hydrogen peroxide, then remaining them in front of UV lamps to mimic the Sun’s rays. The UV bleached absent the pigment-containing parts of lignin but still left the structural components intact, consequently encouraging to keep much more power in the wood.

These much more environmentally welcoming ways support limit the volume of poisonous chemical substances and fossil-dependent polymers used in production, but for now, glass nonetheless has reduce stop-of-existence environmental impacts than clear wood, according to an analysis by Dhar and colleagues in Science of the Full Natural environment. Embracing greener generation techniques and scaling up producing are two methods important to insert transparent wood to mainstream markets, researchers say, but it will consider time. On the other hand, they are confident it can be done and consider in its potential as a sustainable content.

“When you’re trying to reach sustainability, you never only want to match the homes of fossil-dependent components,” Montanari claims. “As a scientist, I want to surpass this.”

This report initially appeared in Knowable Journal, an unbiased journalistic endeavor from Annual Evaluations. Sign up for the newsletter.

[ad_2]

Source website link